Our services

Our operation is characterized by high capacity and technical competence. We have a small and efficient administrative organization that keeps decision-making paths short.

Falkvarv has extensive experience, allowing us to accumulate significant knowledge and technical competence over the years. We have in-house project management, 3D modeling, and a drawing department to assist our customers from project initiation to completion. We also have a well-established network of qualified subcontractors and collaborative partners, enabling us to undertake virtually all shipyard work at short notice. This includes technically complex tasks such as extensive engine conversions.

We offer services for a wide variety of vessels, including tankers, tugboats, cargo ships, workboats, and barges. Additionally, we carry out repairs on research vessels, ferries, and maritime authority vessels on behalf of the government.

Mechanical engineering department

We provide comprehensive service and maintenance for various marine components and equipment, such as auxiliary machinery, steering gear, gearboxes, propellers, pumps, shaft seals, and hydraulics.

Our services also include extensive inspection and service of marine electronics, such as navigation equipment, communication systems, and monitoring tools.

Our goal is to ensure that all critical systems on board the vessel operate correctly, whether they are mechanical, electronic, or hydraulic systems, and that they are in optimal condition. We aim to provide our customers with a secure experience by ensuring that their equipment is in top condition and ready to meet the demands placed on it in maritime environments.

Design department

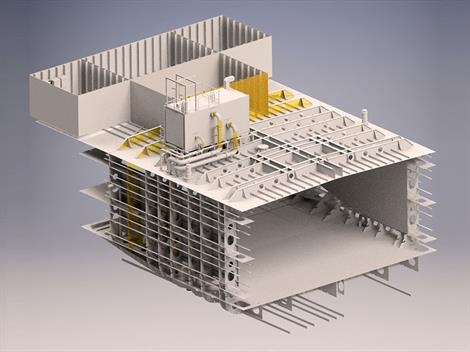

Our internal infrastructure, which is a strong support for our customers, includes project management, advanced 3D modeling, and an experienced design and drawing department. Our strength lies in being a reliable partner who can guide you through the entire project, meaning that we are ready to engage from the very first preparations to the final commissioning. This ensures that the project meets your expectations and set timelines.

With our 3D modeling technology, you can create and visualize your plan in detail before the actual construction process begins. This minimizes the risk of errors and unwanted surprises along the way, allowing you to have a clear and realistic picture of how the project will look and function when completed. This helps address any potential issues before they arise and provides all stakeholders with a common understanding of the project's goals and complexity.

This, in turn, contributes to better communication, collaboration, and decision-making throughout the project's lifecycle.

Welding department

We specialize in welding in steel, stainless steel, and aluminum. Our organization, with its own welding supervisor with IWS certification, enables high control and flexibility. With short notice, we develop the necessary WPQR and WPS for all common welding work on board.

Shall we contact you?

If you want to know more, get a quote or have questions.

Get in touch and we will contact you.